Invented by Norman Joseph Woodland and developed by George Laurer in the 1970s, the barcode was developed as a solution for grocery shops. It was designed to eliminate mounting costs and reduce the labour-intensive task of putting price tags on products.

Fast forward to 2020 and the barcode has developed into several varying types to accommodate its success and adaption into daily life. Barcode and security label specialist, inotec UK, manufactures, supplies and installs barcode and labelling solutions for a range of industries.

When approaching a barcode label specialist company like inotec UK, it is essential to correctly identify which barcode system is needed or currently used. If a customer unknowingly selects the wrong barcode system, it can lead to the whole labelling system being unreadable by the scanning or WMS system installed.

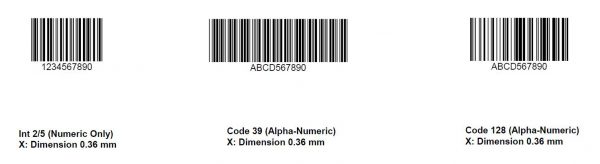

To simplify the process and help customers identify the right solution, inotec has put together a guide for the three most common barcode types.

Barcode Symbology – How are barcodes read?

If you are in doubt as to which barcode system your facility and products use or need, you can often tell just by looking at the barcode’s symbology. You should ignore the first few guard bars on barcodes as they determine the start and finish in case the code is read upside down. If the barcode is scanned upside down, the reader will read the barcode in reverse.

- Interleaved 2 from 5 Barcode (ITF) – Following the guard bars, you will see that 2 in every 5 bars are thick. There will also be 2 wide spaces in every 5 spaces. Both the five lines and wide interleaved spaces represent the digits 1, 2, 4, 7 and 0. The lines and spaces are interleaved and read by a scanner to equate to any number up to 9.

- Code 39 Barcode – Following the guard bars again, on a Code 39 barcode, 2 bars in every 5 are thick. In contrast to Interleaved 2 from 5 barcodes, only one space per 5 bars will be wide. You may also see interspersed sets of 5 thin bars together with 2 wide gaps. This set of 5 thin bars reads symbols only.

- Code 128 Barcode – The Code 128 barcode is a high-density barcode using multi-width lines and multi-width spaces and therefore can be quickly distinguished from Interleaved 2 from 5 and Code 39 barcodes.

Distinguishing and understanding the difference between the three barcode types

- Interleaved 2 from 5 Barcode (ITF)

Interleaved 2 from 5 is a numeric-only barcode which was first developed in 1968. Its format is used to encode pairs of numbers into a self-checking, high-density barcode format. This system reads both the bars and their ‘interleaved’ spaces. Thus reducing the length of the overall code.

The five lines represent the digits 1, 2, 4, 7 and 0. So, for example, the second and fourth digits would equate to ‘9’ (2+7) and the first and fifth digits would equate to ‘1’ (1+0). The second digit in the pair is read within the spaces – there are two wide spaces in the first five lines.

Both the lines and the spaces are interleaved to be read by the scanner. This type of barcode is only suitable for coding with numbers 0-9 and therefore is one of the least commonly used types of barcode.

- Code 39 Barcode

The Code 39 barcode introduces far more variation by allowing upper-case alphabet letters A-Z, the space character and select symbols in addition to numbers for alphanumeric codes. This combination makes them ideal for identifying warehouse items such as racking which often requires a combination of letters and numbers for building letters, aisle letters, pallet position numbers and racking level letters or numbers.

It uses the same principles as the ITF barcode reading 2 wide bars from 5, however, the spaces do not represent a character as with ITF codes. There will only be one wide space in every 5 bars. This space determines which set of digits the 5 bars will represent. There are 4 possible wide space locations within 5 bars, 1, 2, 3 and 4.

The first location will read the bars as U-Z, the second location will read the bars as 1-9, the third location as A-J and the fourth location as K-T. Characters including spaces, $, /, +, and % are represented by 5 x narrow bars with 2 x wide gaps. A long sequence code will result in a long barcode as it reflects the length of the code. Code 39 is a common type of barcode as it is ideal for use on labels for name badges, inventory and industrial applications.

- Code 128 Barcode

Code 128 is a high-density barcode which reduces the code length that would be required compared to Code 39 barcodes. Code 128 barcodes also introduce additional symbols. They can encode all 128 characters of ASCII, hence the 128 reference in the name.

This is one of the most popular types of barcode and is widely used in applications where a relatively large amount of data must be encoded into a relatively small amount of space. The barcode introduces different width bars and gaps. This ultimately allows for more information to be condensed into a smaller barcode.

The popular 128 barcode replaces Code 39 and Interleaved 2 from 5 barcodes as a more compact and flexible code for warehouse and distribution facilities due to its continuous, self-checking bidirectional features. It is also commonly used in the health industry, blood banking and electronics manufacture.

Code 39 vs Code 128 Barcodes

Code 39 and Code 128 are two different types of barcodes with distinct characteristics. Code 128 can encode a full 128 ASCII character set, while Code 39 can encode only 39 characters. Code 128 has a higher density than Code 39. Additionally, Code 128 includes a check digit for error detection, whereas Code 39 does not.

Here’s a comparison table:

| Barcode Types | Code 39 | Code 128 |

| Density | Moderate density | High density |

| Character Set | Alphanumeric with some additional characters | Full ASCII |

| Maximum Capacity | Unlimited (usually 20 to 23 alphanumeric characters) |

Unlimited (usually up to 48 alphanumeric characters)

|

| Error Detection | Self-detection (no check digit required) |

Modulo-103 check digit for error detection

|

| Error Correction | No error correction support |

Mandatory error correction character

|

| Usage Scenarios |

Asset labeling, library books, membership cards, inventory tracking, supply chain, shipping container codes

|

The inotec GmbH head office in Germany is home to its laboratory which develops, tests and produces durable and secure barcode and RFID labelling solutions. As part of the research and testing process, inotec values the importance of the GS1 UK standards to ensure that labels consistently meet the high quality needed for accuracy and reliability.

What is the GS1 UK standard for labels?

The GS1 UK organisation is an industry regulator in charge of standardising the layout and coding system used with labels that are applied to all logistics units such as pallets or crates. The GS1 barcode standard ensures that barcode labels accurately encode information such as product numbers, serial numbers and batch numbers. Barcode labels are essential as they enable parties like retailers, manufacturers and hospitals to automatically identify and track products as they move through the supply chain.

To meet GS1 standards, barcode labels must meet the specified structured layout and data coding criteria. The standards define how barcode digits should be laid out and ordered including additional label check numbers. The GS1 barcode standard dictates the structure of the barcode and order of the digits, for example, check numbers must sit at the end. This standardisation provides a complete guide on how companies and manufacturers should build barcode numbers which ensures that a consistent format is used by all.

The GS1 barcode standard is also responsible for allocating European Article Number codes (EAN). An EAN code is structured in a fixed way and each company or brand name gets assigned its own prefix number. This means that their codes will always start with the same numbers and this identifier can only be used by the individual company.

ISO certification for further labelling standards

In addition to the GS1 standard, inotec also follows the ISO 9001:2000 quality management certification which dictates the standards required for the quality of barcodes to ensure they meet readability expectations and regulatory requirements. Rated from A (best) to F (fail), labels are checked for qualities including the sharpness of the barcode lines and the width between the black and white lines. The ISO certification ensures that all of inotec’s labels meet a standardised quality which is recognisable across the industry.

Monitoring labelling standards – multiple quality checks by inotec

To monitor labelling standards and ensure they are meeting the required criteria, inotec carries out quality checks both before printing a batch of labels and after. When setting up the printers, inotec also prints a test set of labels before production to ensure they print at the required standards.

The production facility uses barcode readers on the different production machines to constantly ensure the barcode labels are readable. Additionally, inotec has specialist software that checks the structure and layout of the codes to ensure they are correct. The software can also simulate barcode reading technology using PDF file previews of the layout of the barcodes. This determines the quality and structure of the barcodes after printing to ensure they will read and print correctly. This includes meeting the GS1 standard criteria for printing the right barcode number structure and barcode lines.

Once the batch is printed, it is then examined by the quality control department at the inotec production facility in Germany. The quality control centre inspects and tests every single label within a batch to ensure they not only meet visual quality checks but also that the barcodes scan correctly and hold data accurately.

The importance of regulating labelling standards

By following the industry standards and meeting its guidelines, inotec’s customers can be assured that its labels are guaranteed to be of the highest quality and durability. At the company’s R & D laboratory in Germany, inotec develops and repeatedly tests its labelling solutions to ensure they achieve the highest standards of readability for ultimate efficiency.

This is especially important for industries including grocery and supermarkets as they need to ensure barcodes on totes and crates can be read accurately at speed and also withstand conditions such as refrigeration and freezing.

In-mould barcode labelling for blue meat crates

Within the food industry, blue plastic meat crates and totes are used throughout Europe for the movement of raw meat from abattoirs and butchers. This has led to a demand within the meat crate industry for in-mould labels.

Throughout Europe, the blue meat crates are made by several different manufacturers but those companies all have one thing in common – they all use inotec’s in-mould labelling technology for the crates. The reason for this is that inotec is capable of meeting the high standards required for in-mould labels used on blue meat crates.

The production of in-mould labels has been awarded to inotec as the GS1 organisation is confident in inotec’s abilities to control data without errors. Furthermore, inotec has the technology and capabilities to fully test in-mould labels for plastic crates and totes in-house to ensure they withstand all possible risk and damage. This is essential for reliability and accuracy.

The importance of choosing high-quality barcode labels that meet labelling standards

Once you understand which type of barcode system your warehouse uses and needs, the next step is to choose a reputable supplier to ensure your labels are printed using high-quality digital print. It is essential your supplier uses digital print to ensure barcode printing is crystal clear.

In production facilities and warehouses, labels often become dirty due to everyday wear and tear as well as general environmental factors such as dust. If dirt was to get stuck between the lines on the barcode labels, it can cause the read of the barcode to fail. Due to the different patterns of the barcode types, the barcode reader needs to be able to recognise the gaps within the barcode. Therefore any dirt or scratches can cause the misread of barcode labels creating many issues.

Furthermore barcodes can become easily scratched during use and movement. This can cause issues such as misread or unreadable barcodes. Having to manually type in the barcode into scanning systems can be lengthy and also allows room for human error and typos.

To protect barcodes from scratches and dirt, inotec UK recommends laminating barcode labels. This extends the life span of barcode labels by protecting them from scratches and allows them to be easily cleaned.

As Europe’s leading warehouse solutions and barcode label supplier, inotec recognises that despite being the least costly part of any installation, incorrect or failing barcode labels are the most common reasons for investments to fail. For example, in warehouses, barcode labels are a small part of the larger system made up of barcode scanners, WMS systems, racking and trucks yet an incorrect barcode label installation will prevent the whole system from working. It is, therefore, essential to get the labelling system correct.

As labelling specialists, inotec can develop unique labelling solutions to meet your production needs including in-mould labels, adhesive labels and RFID labels. If you would like to book a free consultation or speak to the sales team of one of the UK’s most trusted and experienced barcode label supplier, please contact inotec UK on 01482 654466 or email info@inotec.co.uk for more information.