Why it’s important to maintain warehouse line marking

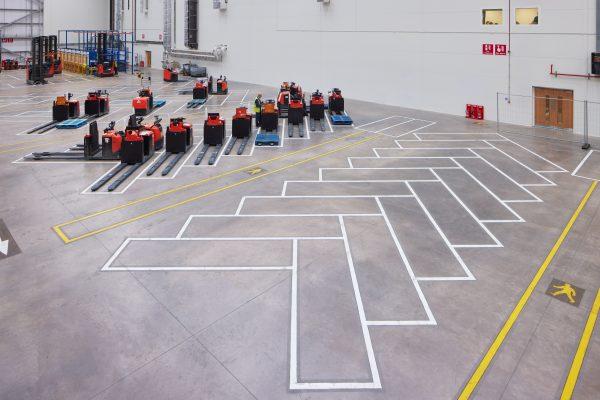

Line marking plays a crucial role in maintaining a safe and efficient workspace within a warehouse environment. However, in a busy warehouse with heavy forklift traffic, harsh chemicals used for floor cleaning and natural wear from footfall, line markings can become damaged, their visibility impaired.

To comply with the UK’s Health and Safety Executive (HSE) floor marking standards it is necessary to keep workers safe and secure within the warehouse environment. This is achieved by the use of clearly marked walkways which segregate truck traffic from vulnerable pedestrians. Hazardous areas and emergency exits are also identified, further contributing to the welfare of workers.

To maintain the effectiveness of warehouse line marking a proactive approach is required with regular inspections and maintenance. Preserving the integrity of line markings in a warehouse with a robust maintenance regime has a number of benefits:

- Line marking remains highly visible and compliant with safety standards

- Staff move easily and efficiently through the warehouse on clearly marked pathways

- Potentially serious accidents due to trip hazards of poorly maintained line marking or impaired visibility of line marking are eliminated

- Downtime is reduced

- Operational efficiency of the warehouse is maximised

How to maintain warehouse line marking

Using a third party expert to carry out regular line marking safety inspection checks, particularly in high traffic areas, ensures that they are done properly, minimising possible hazards and meeting all current regulations. This need not be an expensive exercise, in fact there is one company that will carry out a free maintenance survey and appraisal of warehouse line marking.

A new complimentary safety and maintenance survey has been launched by inotec UK. This free service has been designed to offer advice on essential health and safety requirements of new line marking, upkeep of existing marking as well as replacement lines should they be necessary.

What happens during warehouse line marking maintenance?

There are a number of maintenance procedures that take place:

- A safety and maintenance survey is carried out – to thoroughly assess the current state of line markings in the warehouse.

- Preparation and cleaning – before any maintenance work can begin the affected areas must be free of dust and debris.

- Repainting or repairing – this will be entirely dependent on the condition of the existing line marking. The use of high quality, durable line marking solutions will ensure longevity and visibility.

- Quality control – once the maintenance work has been finished a quality control check is necessary to ensure the line marking is accurate and meets all the necessary safety standards.

- Documentation – a report will be written detailing maintenance work that has been carried out and any future recommendations.

How long does it take to complete the warehouse line marking appraisal and maintenance work?

Naturally the exact duration of maintenance work will depend entirely on the warehouse size and the complexity of work that will be required on the line marking; however the following is a guide to each step of the procedure:

Line marking survey and appraisal

Duration – from a few hours for a simple survey of a smaller warehouse up to a full day for a large site with extensive existing line marking.

Method – an expert will visit the warehouse and appraise the condition of the line marking.

Planning the maintenance

Duration – this usually takes a day or so for large warehouse projects.

Method – a maintenance plan is put together based on the survey findings. It will detail exactly what is required and how long it will take to complete the work.

Completing the maintenance work

Duration – depending on the size and intricacy of the project the maintenance work could take less than a day. Using a team of experts this will be done to minimise downtime of the warehouse operation and ensure normal work can continue.

Method – the line marking maintenance team will carry out repairs or replacement lines as detailed in the maintenance plan.

Post maintenance warehouse quality control and documentation

Duration – A few hours up to half a day

Method – A final quality control inspection is carried out to ensure that the line marking work is accurate, of high quality and meets all safety standards. A detailed report is generated.

How to arrange a free maintenance survey of warehouse line marking

Take a proactive approach to ensure your warehouse line marking is keeping staff safe and compliant with the law by contacting inotec UK. The company will make a site visit to perform a free safety and maintenance survey to appraise your line marking.